Reliability and Intelligent Systems Engineering

In the Reliability and Intelligent Systems Engineering (RISE) Laboratory, research efforts are being taken to create holistic tools that will enable accurate reliability estimation, proactive control of product reliability and operational adjustments to adaptively coordinate product reliability and service logistics, so that the overall uncertainty can be reduced more effectively and globally.

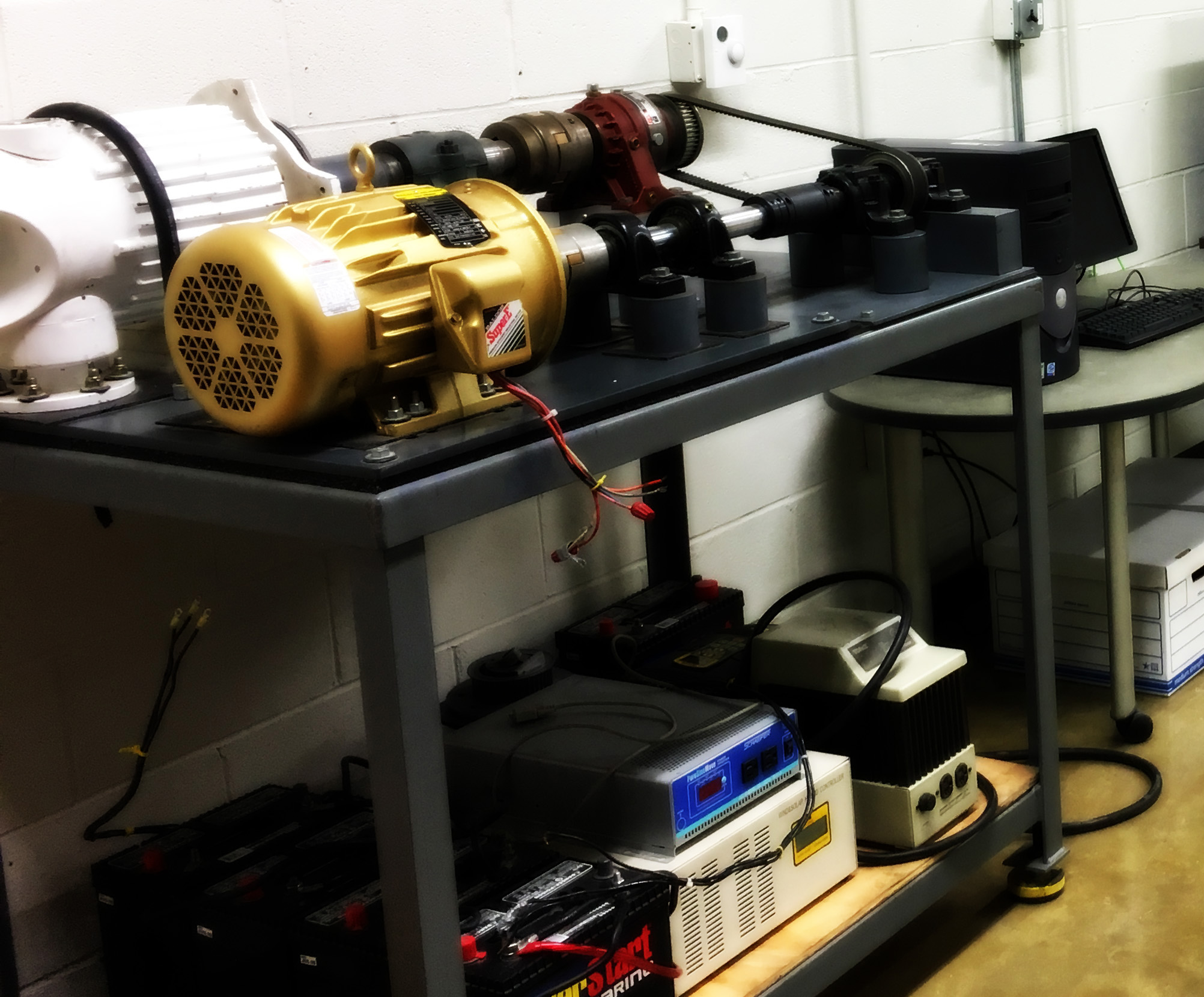

To estimate and improve product reliability, different types of reliability tests

at material and component levels can be conducted. The application areas of our theoretical

and experimental studies include microelectronics, machine tools, electromechanical

components, and nanomaterials. The lab at the UofA’s Engineering Research Center houses

a combined environmental testing facility that provides a product designer with a

full spectrum of analysis on the potential failure modes as well as lifetime and/or

degradation data.

To estimate and improve product reliability, different types of reliability tests

at material and component levels can be conducted. The application areas of our theoretical

and experimental studies include microelectronics, machine tools, electromechanical

components, and nanomaterials. The lab at the UofA’s Engineering Research Center houses

a combined environmental testing facility that provides a product designer with a

full spectrum of analysis on the potential failure modes as well as lifetime and/or

degradation data.

The team has developed a collection of generic models and tools for analyzing accelerated

life or degradation testing data involving complex covariates. Moreover, their previous

research on reducing the energy consumption of such reliability tests will make the

implementations of testing strategies and data analysis more attractive.

The team has developed a collection of generic models and tools for analyzing accelerated

life or degradation testing data involving complex covariates. Moreover, their previous

research on reducing the energy consumption of such reliability tests will make the

implementations of testing strategies and data analysis more attractive.

Indeed, by precisely knowing the reliability of a product under different and time-varying

operating conditions, prognostics, condition-based maintenance and proactive service

logistics can be carried out in a more effectively than ever before.

Indeed, by precisely knowing the reliability of a product under different and time-varying

operating conditions, prognostics, condition-based maintenance and proactive service

logistics can be carried out in a more effectively than ever before.

The other research focuses of this research lab are on data analytics in advanced manufacturing (e.g., additive manufacturing), energy systems, and healthcare.